Product

» »

| YSS | JIS |

Groditz DIN |

Characteristics | Main Applications | Hardness (HRC) | Brochure | |||

|

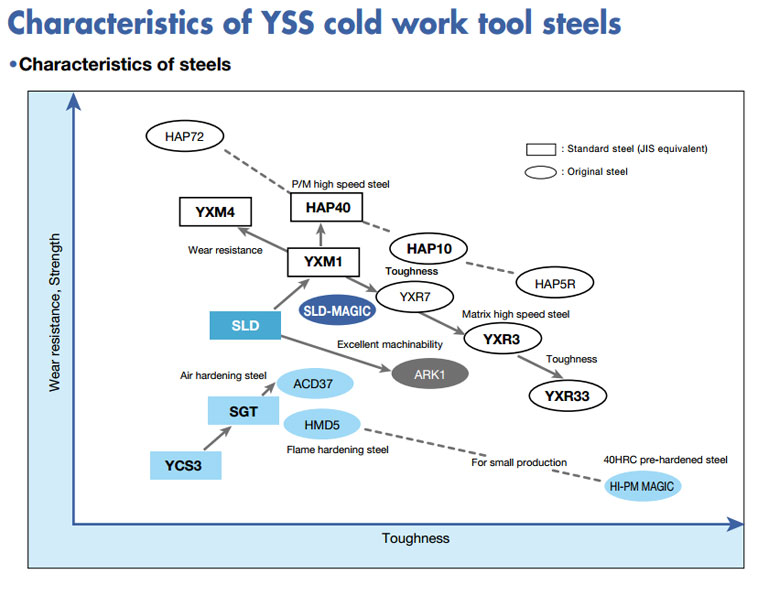

SLD-MAGIC | SLD Improved | High-performance cold work tool steel attaining both extended mold life and easy mold fabrication | Cold work dies for high-tensile steels, SUS, mass production, and general use | 55 - 60 | Download | |||

| SLD | SKD11 | 1.2379 |

Cold work die steel with high abrasion resistance for general use, excellent harden-ability and minimal quench stress |

Cold work dies for general use, forming roll, shear blade. | 55 - 60 | Download | |||

| SGT | SKS3 |

Cold work die steel with superior machinability for general use; Special care is required for quenching large-size dies or wire electric discharge machining |

Dies for deep drawing, gauges | 57 - 63 | |||||

| YCS3 | SKS93 | Carbon tool steel for small production to be quenched in oil improved SK105 grade for its hardenability | Press forming dies, jigs and tools, gauges. | 57 - 63 | |||||

|

YXM1 | High speed steel with high abrasion resistance and toughness for general use | Cold forging dies, cold heading dies, slitter | 58 - 64 | Download | ||||

|

YXR33 | Matrix High Speed Steel (HSS) with highest toughness among High Speed Steels. Excellent strength and erosion resistance at elevated working temperature. | Hot precision forging dies, warm forming dies, or cold forging dies as countermeasure for crack | 54 - 58 | |||||